Featured on Home Page

Improved technology enables fast cutting, clean stripping and simple blade changeover for various size wires.

Read More

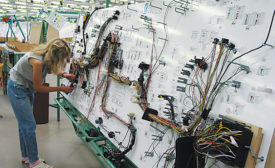

Handling High-Mix Harness Assembly

Organization, flexible equipment and standard work are the keys to handling high-mix production.

July 1, 2016

Additive Manufacturing and End Of Arm Tooling

Innovative 3D-printed end-of-arm tooling enables systems integrator to lighten the load on a robotic packaging line.

July 1, 2016

Selecting the Best Washer for Assembly

Washers perform a variety of functions beyond merely securing threaded fasteners.

July 1, 2016

New Plastics for 3D Printing

Engineers have more material options available than ever

July 1, 2016

The Connected Home Is Here

‘Smart’ appliances are forcing engineers to rethink age-old product designs

June 3, 2016

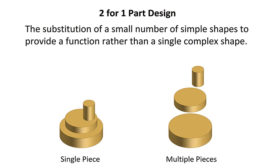

Countering Old-School Views on Design

When designing products, engineers should focus on overall assembly efficiency rather than the cost of individual parts.

June 3, 2016

Assembling Magnesium Parts

Magnesium is strong and lightweight, but it poses problems for fastening and joining.

June 3, 2016

What’s New With Sensors

New technology is helping to make sensors smaller, more robust and easier to integrate.

June 3, 2016

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing