Featured on Home Page

The need for speed, controlled fastening and data gathering continues to push advances in screwdrivers and nutrunners.

Read More

Assembling Wearable Electronics

With the exception of a few critical steps, assembling circuit boards for wearable electronics is no different than assembling conventional circuitry.

May 5, 2016

Leak Testing Auto Parts

The latest automotive systems require innovative leak test methods and fixturing.

May 5, 2016

Automakers and Ergonomics Innovation

Automakers are investing millions of dollars in state-of-the-art technology to keep employees healthy and safe.

May 5, 2016

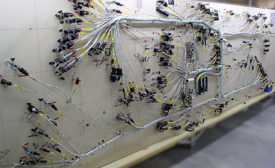

Mixed-Model Assembly Is Key to Profitability

Assembly lines today must be as flexible as possible without compromising efficiency.

May 5, 2016

Power

The Demise of the Electrically Commutated Motors ECMs

The market will expand as ECMs are replaced by more cost-competitive, efficient technologies.

May 1, 2016

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing