Featured on Home Page

The correct approach to data management can transform a business and its ability to serve its marketplace

Read More

Vacuum Grippers Reliably Handle Parts

Suction cups, modular interfaces and specialty grippers reliably handle parts of all shapes and sizes

December 1, 2016

Mastering Changeover

Smooth flow is vital to high-mix production initiatives

December 1, 2016

Modular Automation Components

A wide range of ready-to-install components and subassemblies enable manufacturers and integrators to quickly build custom automated assembly machines.

November 7, 2016

Statistical Process Control of Torque Data on Assembly Lines

Power tools collect a wealth of data about the fastening process, but what can engineers learn from it?

November 7, 2016

What’s New With Machine Vision Systems

New technology is making vision systems faster, more reliable and easier to use.

November 7, 2016

Industry 4.0: Myths vs. Reality

Digital convergence is ushering in a new era of smart factories.

November 3, 2016

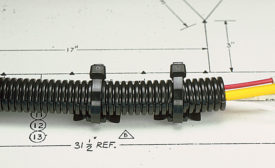

Options for Protecting Wire Harnesses

Wire harnesses need protection in harsh environments.

October 4, 2016

Automated Processing of Small RF and Coax Cables

Ultra-miniature RF cable assemblies require special equipment for cutting, stripping and crimping.

October 4, 2016

Cable Manufacturer Goes From Generally Good to Specifically Great

Guided by a principle from a best-selling book, every Components Express employee focuses on one thing: making the best machine vision cables in the world.

October 4, 2016

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing