Featured on Home Page

A system that runs like clockwork doesn’t happen by accident.

Read More

What’s New With Servo Presses

Needing more precision, energy efficiency and traceability data from their assembly presses, manufacturers are increasingly turning to servo-driven models.

September 8, 2016

Robots Stand Out at Automatica

Suppliers from around the world displayed the latest assembly technology at Automatica 2016.

August 4, 2016

Metal Stitching Joins Dissimilar Materials

Metal stitching can create strong joints in a variety of materials quickly and cost-effectively.

August 4, 2016

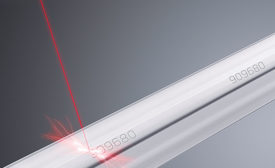

Lasers for Marking Parts

When the application calls for a high volume of parts to be permanently marked, a laser-based system is the best choice.

August 4, 2016

Conformal Coatings Protect Automotive Electronics

Conformal coatings protect and electrically insulate circuit board components from environmental stresses.

August 4, 2016

Orbital and Radial Forming for Delicate Assemblies

New technologies are enabling orbital and radial forming equipment to tackle sophisticated assembly applications.

August 4, 2016

Power Distribution Gets Smart

The ‘smart grid’ is transforming an age-old industry.

August 4, 2016

Special Report: State of the Profession 2016

New tools and technologies help level the playing field.

July 1, 2016

Choose the Best Parts for Your Wire Harness

Each component of a wire harness can affect the performance of the finished product

July 1, 2016

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing