Industries

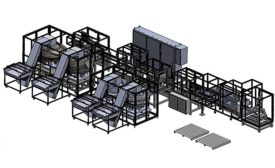

Agile Automation System Assembles Automotive Inverters

The flexible system can produce three variants of the product

November 5, 2019

What’s New With Manual Torque Tools

Today’s manual torque wrenches and screwdrivers collect more data and transfer it wirelessly, providing greater assurance that each threaded fastener is accurately tightened

November 4, 2019

Prototyping Complex Harnesses

Designing, building and testing complex wire harnesses takes planning, attention to detail - and a good tester

October 10, 2019

Interesting and Unusual Applications of Cable Testing

From underwater vehicles to crash dummies, these case studies showcase the benefits of using a versatile and adaptable cable tester

October 9, 2019

Automated Assembly System Roundup

Auto parts, plumbing products and medical devices are among the myriad items made on automated assembly systems

October 4, 2019

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing