Industries

New technology helps engineers gather real-time data on manual assembly processes, such as wire harness assembly.

Read More

Remembering the Assembly--and Repair--of the Hubble Space Telescope

The Hubble Space Telescope launched a new age of astronomy, but assembly snafus nearly created a techno turkey

January 13, 2020

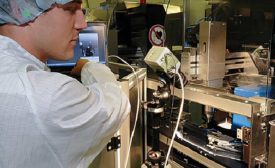

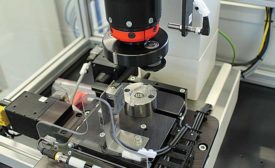

The Appeal of Piezo Jet Valve Dispensing

For applications requiring high speed and precision, cutting-edge piezo jet valve dispensing technology is the way to go

January 9, 2020

Roller Forming for Cylindrical Assemblies

The Roller Forming Process Forms a Curl or Lip on the Edge or Rim of a Hollow, Cylindrical Part

January 8, 2020

Best Practices for Transitioning from Design to Assembly in Medical Device Manufacturing

Design Transfer Can Ensure a Smooth Product Development Process

January 7, 2020

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing