Featured on Home Page

By upgrading gears, cam followers, track rollers and other components, engineers can improve the speed of a machine by 15 to 20 percent or more.

Read More

Assembling Thermoplastic Composites

Joining thermoplastic composites—either to each other or to other materials—can be challenging.

June 7, 2017

Force and Torque Sensors

Advanced technologies increase the accuracy of force and torque sensors used in product assembly and end-of-line testing.

June 7, 2017

Cordless Fastening Comes of Age

Engineers have more battery-powered options available than ever.

June 7, 2017

Understanding and selecting the right process for plastic part assembly

The key variables in assembly and joining operations continue to evolve rapidly.

June 1, 2017

What’s New With Assembly Workstations

More than ever, workstations need to provide ergonomic benefits and design flexibility for changing production needs.

May 5, 2017

Heat-Resistant Adhesives

Epoxies top the list of adhesive chemistries that can take the heat.

May 5, 2017

Rate your suppliers to help them improve

Machinery manufacturer Butler Automatic has developed a unique system to measure the performance of its suppliers and help them improve.

May 5, 2017

Ingress Leak Testing

Engineers have a couple of options for determining if fluids can penetrate an assembly.

May 5, 2017

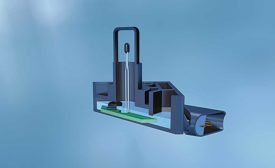

Assembly Presses for High-Force Applications

Applications requiring more than 10 tons of force pose unique challenges for press suppliers.

May 5, 2017

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing