Featured on Home Page

Wearable devices help build better tractors in Jackson, MN.

Read More

Four Sources of Inaccuracy in Sensor Measurements

Electromagnetic signal interference and other factors can adversely affect the measurement accuracy of sensors

September 18, 2017

Best Practices for Press-Fit Assembly

Parts of various sizes, shapes and materials are often assembled with an interference fit.

September 14, 2017

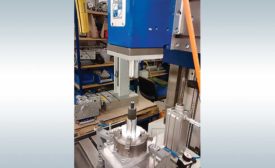

Flexible Assembly Machine Combines Multiple Plastics Joining Processes

What if one machine could be configured to perform any friction-based welding process with a simple change of tooling?

September 12, 2017

Fixed vs. Flexible Automation Systems

Both fixed and flexible technologies offer distinct advantages, but only if manufacturers optimize important operational parameters.

September 8, 2017

Industrial Fastening – Metal Stitching

Metal stitchers can join a wide range of materials including aluminum, copper, brass, plastics, cold rolled steel, hot rolled steel, fabrics, leather, rubber, and galvanized steel.

September 1, 2017

Robots Get Mobile

New technology enables robots to roam about the factory floor.

September 1, 2017

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing