Featured on Home Page

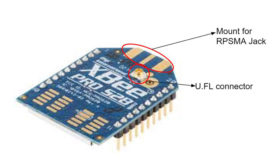

The choice of cable, connector, or antenna relies heavily upon the application.

Read More

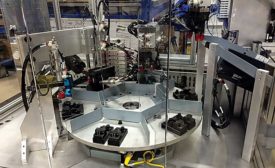

Uncovering Hidden Capacity Using OEE

By monitoring OEE, assemblers can reduce process variability, changeover times, overtime expenditures and capital investments.

October 20, 2017

New Technology for Micro-Dispensing

Noncontact jetting offers distinct advantages over needle-based technology for micro-dispensing applications.

October 19, 2017

Fasteners for Automotive Lightweighting

Hybrid welding-fastener processes join self-piercing riveting as the best technologies for automotive lightweighting.

October 17, 2017

Friction Stir Welding Expands Its Reach

Originally developed for joining aluminum, friction stir welding is now being applied to other materials, including steel, copper, titanium and even nylon.

October 12, 2017

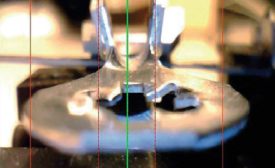

Crimping Small Terminals

Advanced tools and processing equipment are designed to meet the many challenges of crimping small wire.

October 10, 2017

Defending Made-In-The-USA Claims

To claim that a product is “made in the USA,” a manufacturer must make “all or virtually all” of the product in the USA.

October 9, 2017

Wiring Autonomous Vehicles

Next-generation electrical systems will be critical to automated cars.

October 5, 2017

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing