Test and Inspection Assembly

Force-displacement monitoring enables precision assembly of EV drivetrain components

Read More

Robotics

VW Uses Robots to Assemble 300,000 Battery Packs Per Year

Some 100 six-axis robots weld, bond and package EV batteries at the FAW-Volkswagen Automobile Co. Ltd. assembly plant.

July 25, 2023

Design, Manufacture, and Test Efficiently in House

How One Canadian Company Does It

June 21, 2023

Dealing With the Helium Shortage

Assemblers that depend on helium for leak testing are looking for alternatives.

June 12, 2023

Adhesives and Dispensing

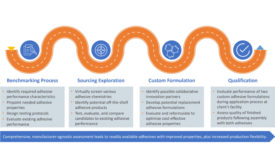

The Sticky Business of Adhesive Sourcing and Replacement

The process of identifying alternative sources for adhesives is more complex than that for other assembly components.

June 1, 2023

Inside GE Appliance's State-of-the-Art Water Heater Assembly Plant

A factory that used to mass-produce refrigerators now assembles water heaters.

May 1, 2023

Vision System Inspects Bearing Assemblies

High-speed cameras met cycle time requirement of less than one second.

April 12, 2023

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing