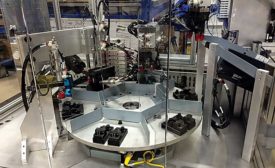

Automated Assembly Systems

Flexible feed and drive systems improve productivity.

Read More

Translating Manufacturing Data for the IIoT

An MES gateway appliance translates, rather than transfers, production line data for secure and reliable exchange with IT databases.

January 9, 2018

Automation Gives Medical Device Manufacturer a Shot in the Arm

Collaborative robots help improve productivity and reduce costs.

January 3, 2018

What Is IO-Link?

New technology enables sensors and actuators to become smarter.

December 14, 2017

ASSEMBLY Capital Spending Report 2017: Capital Spending Continues to Increase

With the economy firing on all cylinders, our annual Capital Equipment Spending Survey predicts continued growth in investment.

December 1, 2017

Manufacturing Execution Systems Meet the Cloud

MES are essential to digital production initiatives.

November 9, 2017

Uncovering Hidden Capacity Using OEE

By monitoring OEE, assemblers can reduce process variability, changeover times, overtime expenditures and capital investments.

October 20, 2017

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing