Automated Assembly Systems

Both fixed and flexible technologies offer distinct advantages, but only if manufacturers optimize important operational parameters.

Read More

What’s New With RFID

RFID technology has become critical for assembling cars, appliances and other high-value, high-mix products.

August 7, 2017

Assembly Automation

What IIoT Means for Manufacturing: How the Industrial Internet of Things Can Enhance Efficiencies Throughout the Factory

June 16, 2017

Behind the Scenes at DeWALT

DEWALT’s assembly plant in Charlotte, NC, produces high-quality tools while beating overseas competition.

June 7, 2017

advertisement

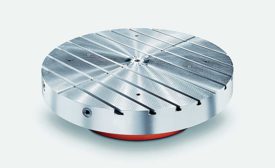

How To Eliminate Output Overloads and Maintenance In Your Index Table Applications

April 26, 2017

advertisement

How To Deliver Automation Excellence In Today’s Fast-Paced Environment

April 25, 2017

advertisement

How To Be prepared for the future…

The Rotary Table that thinks and learns.

April 25, 2017

What’s New With Six-Axis Robots?

Today, collaboration is the name of the game.

April 10, 2017

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing