Automated Assembly Systems

Project Management for Assembly Automation

When purchasing an automated assembly system, plan well, build on the experience of others, and work with a solid team.

March 11, 2019

Increasing Lead Times for Automation Components Become an Issue for Systems Integrators

As demand for automation increases, lead times for components are increasing

February 6, 2019

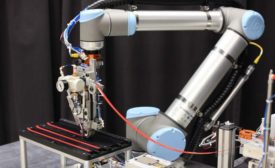

Robotic Screwdriving Comes of Age

New technology makes it easier to automate fastening applications

February 5, 2019

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing