Automated Assembly Systems

Used within the IIoT, edge computing offers benefits that range from reducing network latency and plant accidents, to achieving predictive maintenance and maximizing uptime

Read More

5G Will Drive Tomorrow’s Connected Assembly Lines

Next-generation wireless technology is transforming production processes

May 15, 2020

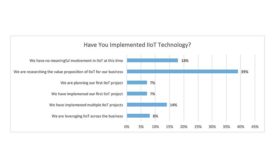

Assemblers See Promise—and Challenges—in IIoT

Our exclusive new survey reveals assemblers’ usage, plans and expectations for the Industrial Internet of Things

May 15, 2020

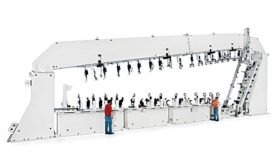

Alternatives to Pallet-Transfer Conveyors

Need to linearly index parts and subassemblies with accuracy and repeatability? Consider precision-link conveyors and walking beams

April 3, 2020

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing