Home » assembly machine

Articles Tagged with ''assembly machine''

2020 Capital Spending Survey: Cautious Optimism

With a new presidential administration and an end to COVID in sight, manufacturers are ready to invest in their assembly lines.

December 4, 2020

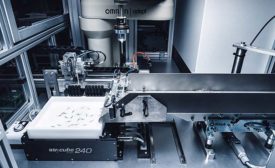

Smart Transport System Enables Flexible Assembly

A linear-motor transport system is the heart of a new, flexible automated assembly system.

November 9, 2020

What’s New With Rotary Indexers

Servo indexing and flexibility drive numerous assembly applications.

November 6, 2020

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing