Home » assembly machine

Articles Tagged with ''assembly machine''

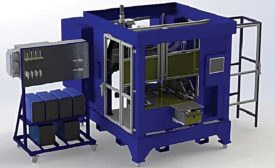

Several technologies ensure that automated machines meet ANSI, ISO, ISA and OSHA safety standards

Read More

Next-Gen SCARA Robots

State-of-the-art SCARA robots are helping assemblers meet greater demand for speed and precision

April 2, 2018

Flexible Fixtures for Automated Assembly

Researchers have developed a hexapod-based reconfigurable fixture that can be used to assemble a family of automotive headlights.

March 5, 2018

Rotary Actuators for Automated Assembly

Decades-long refinement makes today’s rotary actuators more precise and versatile than ever

February 6, 2018

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing