Home » assembly machine

Articles Tagged with ''assembly machine''

Magnetic Pulse Welding for EV Assembly

The electric vehicle revolution is generating new interest in an old technology: magnetic pulse welding.

July 12, 2023

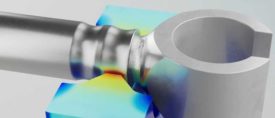

Optimizing Work Cells for Press-fit Assembly

There are many ways to boost productivity in pressing operations.

June 27, 2023

Semiautomatic Welding Cells

Not all welding applications need to be fully automated.

June 26, 2023

Options for Semiautomatic Dispensing

Handheld, powered dispensers provide the answer to many assemblers’ needs.

June 26, 2023

Best Practices for Semiautomatic Screwdriving

The cost of fasteners is often not as important as the cost of installing them.

June 25, 2023

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing