Home » additive manufacturing

Articles Tagged with ''additive manufacturing''

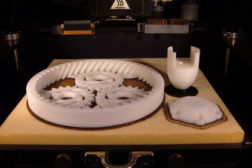

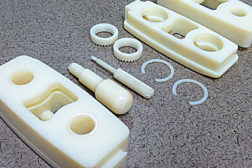

Does 3D Printing Work with Wiring?

Additive manufacturing can be used to produce connectors and terminals.

October 1, 2013

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing