Home » additive manufacturing

Articles Tagged with ''additive manufacturing''

Additive Manufacturing and End Of Arm Tooling

Innovative 3D-printed end-of-arm tooling enables systems integrator to lighten the load on a robotic packaging line.

July 1, 2016

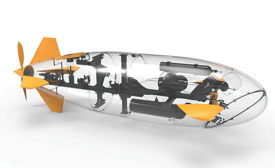

New Plastics for 3D Printing

Engineers have more material options available than ever

July 1, 2016

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing