Home » additive manufacturing

Articles Tagged with ''additive manufacturing''

General Electric has been building aircraft engines since the dawn of the Jet Age.

Read More

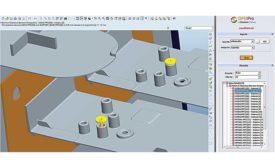

Design for Additive Manufacturing

Several factors should be considered at the design stage to effectively produce parts using additive manufacturing methods.

March 1, 2017

Consolidated Part Assemblies

Consolidating complex parts assembled from many components into one 3D-printed design saves time and money.

February 1, 2017

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing