Home » flexible assembly

Articles Tagged with ''flexible assembly''

Heavy duty rollers accommodate large and small totes.

Read More

What’s New With Conveyors

Conveyors remain essential for getting parts to the right spot at the right time. Here’s a look at the state of the art.

May 5, 2023

Inside GE Appliance's State-of-the-Art Water Heater Assembly Plant

A factory that used to mass-produce refrigerators now assembles water heaters.

May 1, 2023

Vision System Inspects Bearing Assemblies

High-speed cameras met cycle time requirement of less than one second.

April 12, 2023

Robots, People Collaborate on Product Assembly

A cobot with a special gripper from the Zimmer Group improves ergonomics and productivity on Weidmüller’s assembly line.

April 11, 2023

Cobots Perform Screwdriving and Packaging for Tool Manufacturing Company

Cobots optimize assembly and packaging by 30 percent.

April 7, 2023

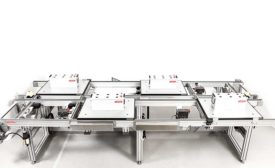

Flexible Automation Boosts Battery Production

Standardized, software-driven assembly cells enable start-up to manufacture batteries domestically.

April 6, 2023

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing