Home » flexible assembly

Articles Tagged with ''flexible assembly''

Options for Semiautomatic Dispensing

Handheld, powered dispensers provide the answer to many assemblers’ needs.

June 26, 2023

Best Practices for Semiautomatic Screwdriving

The cost of fasteners is often not as important as the cost of installing them.

June 25, 2023

Manual, Semiautomatic or Fully Automatic?

The degree of automation on an assembly line depends on such factors as production volume, variety, complexity and cost.

June 25, 2023

Automated Dispensing for EV Motor Assembly

A fully automated line dispenses and cures a filled, two-part epoxy to encapsulate bus bars for ev motors.

June 8, 2023

Renault Retrofits Robots at Refactory

By rehabbing its own used robots, renault saves money and reduces delivery times.

May 10, 2023

Software Simplifies Programming of Robots

New software enables defense contractor to program robots quickly and easily for high-mix production.

May 9, 2023

Robotics

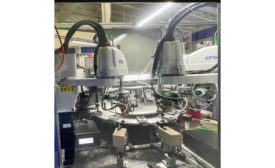

SCARA Robots Solder Circuit Assemblies

Electronics assembler’s DIY automation project saves money and increases efficiency.

May 8, 2023

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing