Home » flexible assembly

Articles Tagged with ''flexible assembly''

New technologies are helping assemblers keep track of product on the line.

Read More

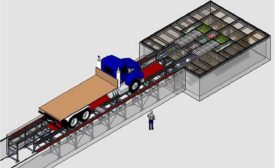

Conveyor Case Studies

With the right conveyor, manufacturers can greatly improve their assembly, part feeding and packaging processes.

July 15, 2022

The Right Robot for the Job

Systems integrator mixes and matches SCARA robots for medical device assembly line.

May 12, 2022

Justifying Investment in Automation

Production ‘pain points’ should be identified and well documented.

March 31, 2022

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing