Home » Keywords: » cost reduction

Items Tagged with 'cost reduction'

ARTICLES

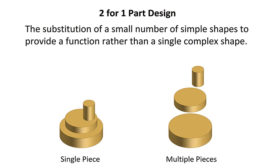

Countering Old-School Views on Design

When designing products, engineers should focus on overall assembly efficiency rather than the cost of individual parts.

June 3, 2016

EVENTS

Webinar Webinar

6/12/24 to 6/12/25

Contact: Meg K.

Conveyors in Industry 4.0: Essential Solutions for Evolving Manufacturing Landscapes

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing