Home » Keywords: » virtual reality

Items Tagged with 'virtual reality'

ARTICLES

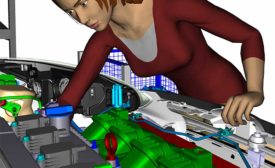

The Reality of Augmented Reality

Wearable devices empower assemblers to be more productive

May 7, 2019

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing