Articles by Jim Camillo

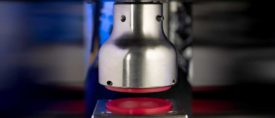

Spin Welding for Plastics Assembly

Enhanced data gathering and automation features complement spin welding’s ability to join plastic parts with a round-to-round interface.

February 1, 2022

Harness Shop Masters Difficult Wire Assemblies

For Chief Enterprises LLC, the formula for success is straightforward: Build the uncommon wire harnesses that no other shop wants to.

January 12, 2022

All About Blind Riveting

The benefits of blind riveting go way beyond the ability to install a fastener from only one side of a part or structure.

January 6, 2022

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing