Articles by Jim Camillo

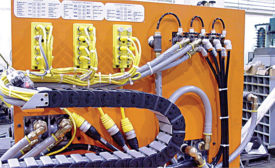

Automatic Cutting and Stripping Machines

Improved technology enables fast cutting, clean stripping and simple blade changeover for various size wires.

July 1, 2016

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing