News

Contact Lens Manufacturer Employs Solar Power to Safeguard Production

Solar panels reduce manufacturer’s annual electricity bill by $325,000.

January 9, 2024

Robotics

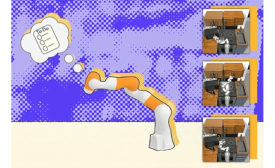

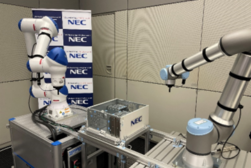

Multiple AI Models Help Robots Execute Complex Plans

A multimodal system uses models trained on language, vision and action data to help robots develop and execute plans for household, construction and manufacturing tasks.

January 9, 2024

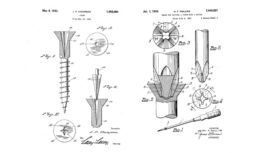

How One Patented Screw Increased Speed in Automotive Assembly

A Brief History of the Phillips Screw

January 2, 2024

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing