Motion Control

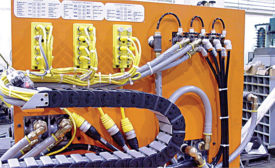

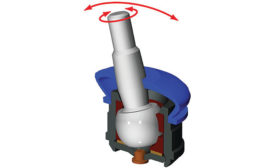

Innovative Conveyors Maximize Use of Space

New conveyor technologies are giving plant managers more options to make better use of existing space.

September 8, 2016

advertisement

How to Choose Between Electric and Pneumatic Actuators and Grippers

March 8, 2016

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing