Electronics Assembly

Dispensing Thick Materials

Precise valves and powerful pumps are essential to properly dispense one- and two-component high-viscosity materials.

January 5, 2017

Cable Manufacturer Goes From Generally Good to Specifically Great

Guided by a principle from a best-selling book, every Components Express employee focuses on one thing: making the best machine vision cables in the world.

October 4, 2016

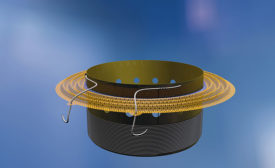

Adhesives for Speaker Assembly

Light-curing adhesives can help speaker manufacturers increase efficiency.

October 3, 2016

Bullet-Proof Automated Assembly

A system that runs like clockwork doesn’t happen by accident.

September 8, 2016

What’s New With Servo Presses

Needing more precision, energy efficiency and traceability data from their assembly presses, manufacturers are increasingly turning to servo-driven models.

September 8, 2016

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing