Electronics Assembly

Joining Wire to Small Metal Parts

State-of-the-art welding and soldering equipment ensure that wires are securely joined to terminals or other wires.

July 5, 2017

Feeding and Driving Small Screws

Specialized equipment is needed to feed and drive very small screws.

July 5, 2017

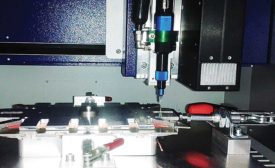

Dispensing Fluids for Portable Electronics

Manufacturers need equipment versatile enough to accurately dispense materials ranging from thin adhesives to thick solder paste.

July 5, 2017

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing