Wire Processing Assembly

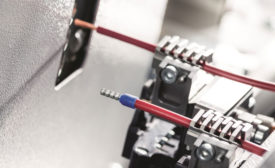

Advanced servo technology ensures quick machine setup, precise wire processing and high production.

Read More

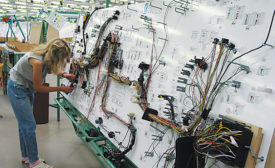

Wire Harness Manufacturer Produces Quality Products in the Heartland

Indiana-based ALTEX relies on error-proofing and industry standards to ensure quality harness assembly.

January 6, 2017

The Impact of the LV 214-4 Standard

A new standard developed by German automotive OEMs provides insight into crimp force monitoring.

January 6, 2017

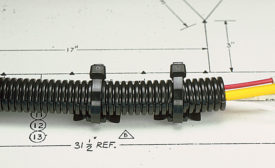

Options for Protecting Wire Harnesses

Wire harnesses need protection in harsh environments.

October 4, 2016

Automated Processing of Small RF and Coax Cables

Ultra-miniature RF cable assemblies require special equipment for cutting, stripping and crimping.

October 4, 2016

Cable Manufacturer Goes From Generally Good to Specifically Great

Guided by a principle from a best-selling book, every Components Express employee focuses on one thing: making the best machine vision cables in the world.

October 4, 2016

Choose the Best Parts for Your Wire Harness

Each component of a wire harness can affect the performance of the finished product

July 1, 2016

Automatic Cutting and Stripping Machines

Improved technology enables fast cutting, clean stripping and simple blade changeover for various size wires.

July 1, 2016

Handling High-Mix Harness Assembly

Organization, flexible equipment and standard work are the keys to handling high-mix production.

July 1, 2016

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing