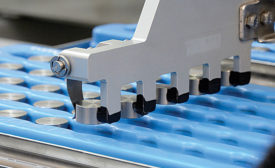

Robotics Assembly

Robots Stand Out at Automatica

Suppliers from around the world displayed the latest assembly technology at Automatica 2016.

August 4, 2016

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing