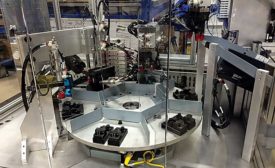

Robotics Assembly

Washington State Seeks to Automate Apple Orchards

Apples require a system that’s delicate, gentle and fast.

November 3, 2017

Uncovering Hidden Capacity Using OEE

By monitoring OEE, assemblers can reduce process variability, changeover times, overtime expenditures and capital investments.

October 20, 2017

Robots Get Mobile

New technology enables robots to roam about the factory floor.

September 1, 2017

Force and Torque Sensors

Advanced technologies increase the accuracy of force and torque sensors used in product assembly and end-of-line testing.

June 7, 2017

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing