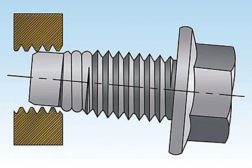

Screwdriving and Riveting Assembly

The Importance of Torque Auditing

Accurate tooling and proper training are the keys to maintaining the specified torque for each threaded fastener.

November 1, 2013

New Materials Allow Soldiers to Shed Weight

The U.S. Army is enlisting more aluminum and composites.

November 1, 2013

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing