Screwdriving and Riveting Assembly

New Materials Spur Innovation in Sporting Goods Manufacturing

Engineers are scrambling to make products stronger, lighter and smarter.

November 3, 2014

Torque Testing Equipment

Regular calibration with torque testing equipment keeps fastening tools accurate on the line.

November 3, 2014

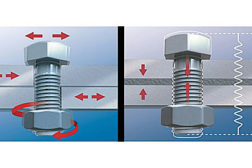

Fasteners vs. Vibration

Manufacturers rely on specialty bolts, nuts and threadlockers to keep fasteners tight and immune to vibration.

October 3, 2014

2014 Assembly Plant of the Year

Assembly Plant of the Year: STIHL Stays a Cut Above the Competition

Flexible assembly lines and vertical integration thrive in Virginia Beach.

October 3, 2014

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing