Automated Assembly Systems

Automated Epoxy Plant Has More Flexibility

Established in 2002, Polystar LLC produces a full line of chemicals for epoxies used in assembly applications

March 1, 2013

Ford and Toyota Celebrate Historic Milestones

Ford Motor Co. and Toyota Motor Corp., the two companies that pioneered mass production and lean manufacturing, are each celebrating important milestones this year.

March 1, 2013

Solve the Demand-Driven Supply Chain Problem

Electronic kanban systems can help manufacturers avoid the bullwhip effect.

March 1, 2013

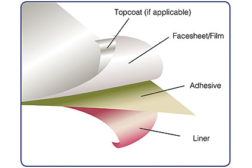

Five Steps to Picking the Best Label

The answers to these five questions will help you pick the perfect label for your application.

March 1, 2013

Colleague Robot Ensures Flawless Car Seat Assembly

At Lear Corp.’s production facility in Besigheim, Germany, multiple shifts of workers assemble car seats just-in-time.

March 1, 2013

Robotics and 3D Printing Get Creative at Cornell Lab

Robotic grippers and 3D printing are two passions of Hod Lipson, an associate professor of mechanical and aerospace engineering and computer science at Cornell University.

March 1, 2013

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing