Automated Assembly Systems

Honey-Dos and the Assembly Line

Has a hobby or home improvement project ever informed your work on the assembly line?

May 6, 2013

The Challenge of Flexibility in Leak Testing

Market conditions demand manufacturers use equipment that accommodates, and accurately tests, a wider variety of parts.

May 1, 2013

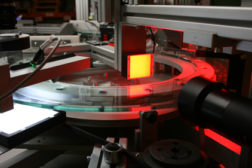

Considerations for Selecting Vision Systems

In the first of a series of primer articles on machine vision, the author starts with the most important component—the camera.

May 1, 2013

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing