Appliance Assembly

Fastening & Joining

The following considerations can help point the way toward application success.

Read More

Smart Appliances and a Future of Interoperability

Data communications standards can enable appliance manufacturers to achieve robust growth.

March 1, 2019

Ergonomic Guide to a Safer, More Efficient Connector-Assembly Workplace

Understand key issues in connector and workplace design to improve worker and product performance.

February 15, 2019

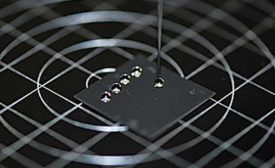

Flow-Fasteners for HVAC Assembly Challenges

Flexibility should be of utmost importance when selecting an assembly joining system.

February 8, 2019

New Applications for High-Strength Tapes

Acrylic foam and glazing tapes can often replace fasteners or liquid adhesive in many applications

December 13, 2018

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing