Home » lightweighting

Articles Tagged with ''lightweighting''

The EV Lightweighting Challenge

Lightweighting efforts focus on new materials to improve operating range.

February 9, 2023

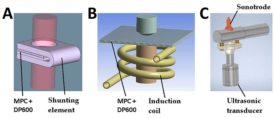

Spot Welding Metal-Plastic Composites

A new resistance spot welding process can join metal-plastic composites

April 7, 2022

Reducing Weight of Electric Vehicles

Lightweighting Drives EV Range and Performance

September 9, 2021

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing