Home » Industry 4.0

Articles Tagged with ''Industry 4.0''

Mercedes’ new assembly plant sets standards for flexibility, efficiency, sustainability and digital production.

Read More

advertisement

From IIoT Connectivity to Context - Powering Data-Driven Industrial Transformation in Your Factory

September 16, 2020

Factory of the Future

Mercedes-Benz Deploys IoT, AI Technology at Alabama Assembly Plant

August 12, 2020

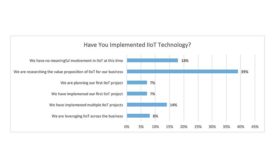

Assemblers See Promise—and Challenges—in IIoT

Our exclusive new survey reveals assemblers’ usage, plans and expectations for the Industrial Internet of Things

May 15, 2020

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing