Home » automatic screwdriving

Articles Tagged with ''automatic screwdriving''

advertisement

How to Provide Maximum Processing Reliability on a Manual Screwdriving Workstation

March 8, 2016

advertisement

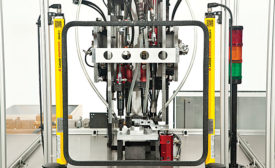

How To Self Program and Robotically Fasten Multiple Parts on One Assembly Machine

March 7, 2016

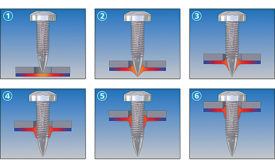

Feeding Nuts and Unconventional Fasteners

Custom design and advanced technology enable feeders to handle a wide range of threaded, nonthreaded and odd-shaped fasteners.

July 1, 2014

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing