Home » automatic screwdriving

Articles Tagged with ''automatic screwdriving''

Error-Proof Screwdriving

Technological advances in manual and power tools make repeatable error-proof screwdriving an achievable goal for manufacturers.

November 8, 2021

Dürr Helps Volkswagen Go All-In on EV Assembly

Flexible automated equipment drives screws, dispenses adhesive and fills refrigerants.

August 6, 2021

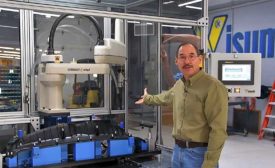

Automatic Screwdriving Opens Window to Productivity

A systems integrator, a motor manufacturer and a screwdriving supplier collaborate to increase productivity and quality at ROMA.

February 5, 2021

Threaded Fasteners for Plastics Assembly

Here are some tips, tricks and suggestions for using threaded fasteners to assemble plastic parts

April 7, 2020

New Technology for Automatic Screwdriving

Collaborative robots are among the latest products for automatic screwdriving

February 5, 2020

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing