Home » factory automation

Articles Tagged with ''factory automation''

The Right Robot for the Job

Systems integrator mixes and matches SCARA robots for medical device assembly line.

May 12, 2022

Press Fitting Railcar Wheelsets

The force-displacement curve can be influenced by part geometry, coefficient of friction, material strength and operating conditions.

May 5, 2022

Leak Testing Appliances

Mass flow, pressure or vacuum decay, and tracer gas sniffing tests ensure leak-free performance of all types of home appliances.

May 4, 2022

Beyond the Welding Line: Robots and Automotive Assembly

Humans and machines are collaborating on trim lines.

April 12, 2022

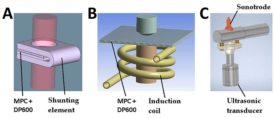

Spot Welding Metal-Plastic Composites

A new resistance spot welding process can join metal-plastic composites

April 7, 2022

Best Practices for Conveyor Maintenance

Timely and proper maintenance is essential for all key conveyor components.

April 4, 2022

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing