Home » factory automation

Articles Tagged with ''factory automation''

New technologies are helping assemblers keep track of product on the line.

Read More

Troubleshooting the Stripping and Crimping Process

Simple error-proofing steps can help avoid big headaches.

July 21, 2022

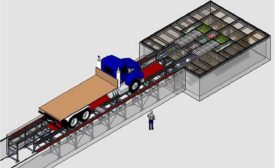

Conveyor Case Studies

With the right conveyor, manufacturers can greatly improve their assembly, part feeding and packaging processes.

July 15, 2022

VW and the Cloud

By creating an industrial cloud, VW hopes to improve systemwide productivity by 30 percent.

June 30, 2022

Smart Manufacturing at Audi

Digital transformation is well underway at Audi’s five assembly plants worldwide.

June 29, 2022

BMW Applies AI to Assembly

AI is helping BMW inspect parts, control processes and route AGVs.

June 29, 2022

Industry 4.0 at Škoda

Digital twins, autonomous mobile robots and AI are some of the cutting-edge technologies helping European automaker Škoda compete.

June 28, 2022

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing