Home » process monitoring

Articles Tagged with ''process monitoring''

The correct approach to data management can transform a business and its ability to serve its marketplace

Read More

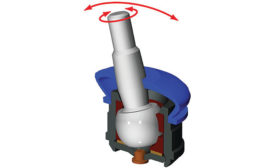

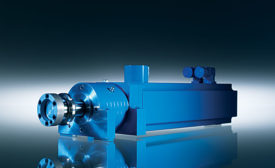

Orbital and Radial Forming for Delicate Assemblies

New technologies are enabling orbital and radial forming equipment to tackle sophisticated assembly applications.

August 4, 2016

advertisement

How To Select the Right Electromechanical Servo Press for Your Assembly Operation

March 8, 2016

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing