Home » press-fit assembly

Articles Tagged with ''press-fit assembly''

Assembly Presses

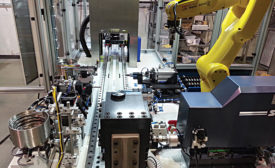

Handheld Servo Press Tops Lineup of New Press Technologies at ASSEMBLY Show

May 17, 2017

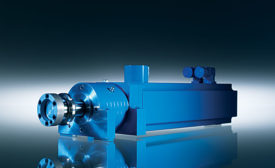

Assembly Presses for High-Force Applications

Applications requiring more than 10 tons of force pose unique challenges for press suppliers.

May 5, 2017

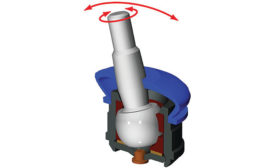

What’s New With Servo Presses

Needing more precision, energy efficiency and traceability data from their assembly presses, manufacturers are increasingly turning to servo-driven models.

September 8, 2016

advertisement

How To Select the Right Electromechanical Servo Press for Your Assembly Operation

March 8, 2016

advertisement

How To Determine the appropriate press technology for high-force, high-speed applications.

March 7, 2016

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing