Home » additive manufacturing

Articles Tagged with ''additive manufacturing''

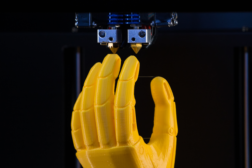

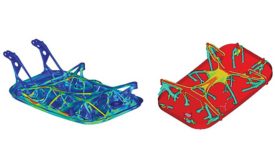

Additive Manufacturing: The Quest for Automation

Robots and other tools are key to mass-producing printed parts

July 9, 2019

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing