Wire Processing Products

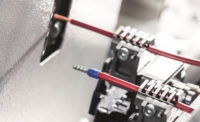

Automatic Cut, Strip and Crimp Machine

Image courtesy of Komax Corp.

The Alpha 550 G2 is a fully automatic system for cutting, stripping and crimping wire with cross-sections ranging from 0.13 to 6 square millimeters. Powerful servomotors position the swivel arm accurately and repeatably. Maximum wire feed speed is 12 meters per second. The infeed and outfeed systems adapt automatically to each other to ensure constant optimum throughput and high Cpk values. The machine can be integrated into a production control system.

An optimized setup process keeps production interruptions as short as possible. Its modular design and customizable software make it future-proof for increased automation. A common parts concept maximizes efficiency, reduces costs and simplifies maintenance. A seal insertion module automatically loads wires with industry-standard seals and miniature grommets.

Fully automated quality monitoring with minimal operator influence ensures perfect results and minimal waste. An optical crimp monitoring station visually checks stripping quality and automatically rejects faulty products. A seal monitoring function is available to check seal position and orientation. A high-performance color vision system detects crimp defects, such as crimped-on strands or insulation in the crimp. Product quality can be tracked using statistics, image saving and network feedback.

The intuitive HMI features programmable process flows and customized dashboards in more than 25 languages. Operators are guided through the processes smoothly and efficiently.

See this company at The ASSEMBLY Show South May 1-2 in Nashville, TN.

Komax Corp.

www.komaxgroup.com/en

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!