Home » Keywords: » automatic stripping and crimping

Items Tagged with 'automatic stripping and crimping'

ARTICLES

Troubleshooting the Stripping and Crimping Process

Simple error-proofing steps can help avoid big headaches.

July 21, 2022

Processing Automotive Ethernet Cables

Ethernet cables provide high-speed data transmission for infotainment and driver assistance applications, but they require automated equipment for stripping and crimping.

January 14, 2022

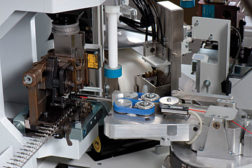

What’s New With Cut, Strip and Crimp Machines

These fully automated machines simultaneously process the ends of one or more different wires to optimize productivity

January 13, 2021

Options for Tinning Wire

Whether applied manually or by a machine, the tinning process improves the mechanical strength of bare copper wire

April 10, 2020

Wire Processing

Should You Invest in Fully Automatic Stripping and Crimping Machines?

if you need to produce thousands of identical crimped wires in a shift, you need a fully automatic cutting, stripping and crimping system.

January 3, 2013

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing